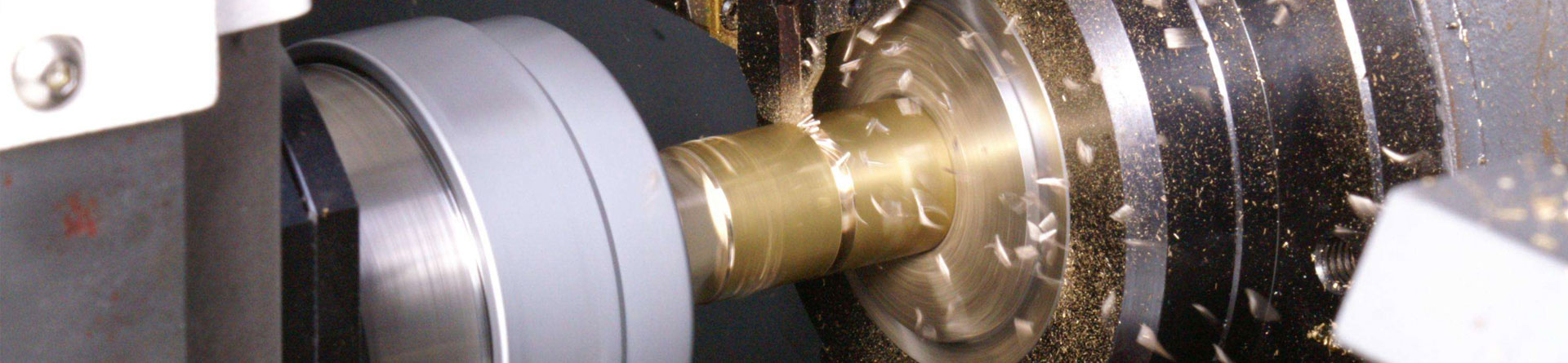

CNC Machining Brass Parts

Brass is an alloy made from copper and zinc, with strong wear resistance, ow coefficient of friction, low melting point, good malleability, and high corrosion resistance, it’s incredibly useful for hot machinery and products. So the brass is an ideal material for manufacturing CNC machining parts. And precision machined brass parts are one of the most commonly used metal CNC parts, which are often used to make valves, water pipes, air conditioning connecting pipes and radiators. they can be found in electrical products as well as plumbing, the medical industry, and many consumer products.

Brass Precision CNC Machined Components For Sale – China CNC Brass Machining Parts Supplier

Looking for precision brass parts machined by an experienced and reliable CNC components manufacturer? Junying’s custom brass machining services can be your ideal choice. We have over 10 years of CNC machining experience, have capabilities to manufacture simple or complex brass products including high quality precision brass CNC milled components, brass CNC turned components and brass CNC drilling components to meet your demands with reliable operators, sophisticated machinery and equipment at our disposal. The CNC machined brass parts we produce are non-magnetic, easy to cast, and usually doesn’t require surface finishing. All of our brass machined components are subject to our rigorous inspection regime with designated inspectors, in-process inspection and a full final inspection completed on every part.

Features & Advantages Of Custom Machining Brass CNC Parts

– Brass parts & components provide tighter seals for fittings

– Can cut down on production costs and is extremely strong under high stress

– Can withstand extreme temperatures

– Easy to cast

– High heat and corrosion resistance, rustproof and more premium properties

– Extremely durable and long service life

– Low weight and easy to take or install

Applications: