What is Black Oxide or Blackening | Junying Custom Metal Finishing Services

Protective and Aesthetic Black Oxide (Blackening) Services

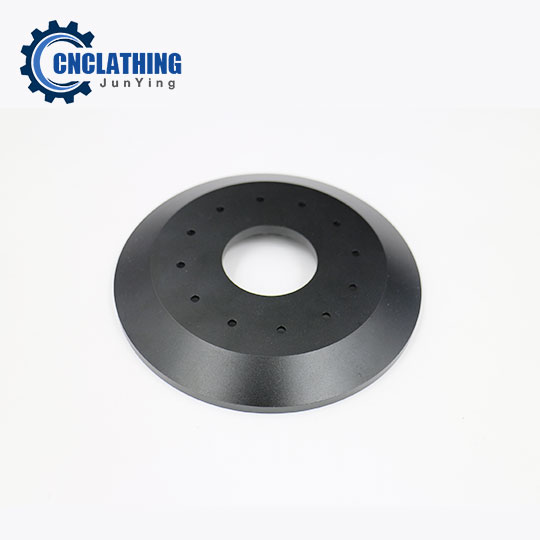

Experience superior metal enhancement with our professional black oxide finishing services, delivering an exceptional combination of aesthetics and functionality. Our advanced blackening processes, including cutting-edge mid-temperature blackening and environmentally-conscious alkaline treatments, create a striking uniform matte or glossy black finish that seamlessly adheres to ferrous metals, tool steels, and powdered metals with precision thickness control of 0-30μm. Unlike conventional coatings that risk flaking or peeling, our black oxide finish becomes an integral part of the metal surface, offering reliable corrosion protection that’s further enhanced when oil-impregnated, while also providing crucial light reflection reduction. The remarkably durable finish can only be removed through mechanical or chemical means, ensuring long-lasting performance for your components. Whether you’re looking to enhance the appearance of tools and fixtures or require superior corrosion resistance for critical components, our black oxide surface finishing service stands as an economical and reliable solution for improving the properties of your metal parts.

What Is Black Oxide and How Does It Work?

Black oxide is a chemical conversion coating, meaning it’s not a deposited layer like electroplating. Instead, it’s a chemical reaction between the metal’s surface and an oxidizing solution. This solution contains oxidizing salts, penetrants, catalysts, activators, and proprietary additives that react with the iron in ferrous metals to create magnetite (Fe3O4). This thin black layer (typically 1-2 micrometers thick) becomes integral to the metal’s surface. While offering some corrosion resistance, black oxide often requires a sealant like oil or wax for optimal protection.

What Is the Process of Black Oxide Surface Treatment?

The black oxide process creates a protective and aesthetically pleasing black iron oxide (magnetite, Fe3O4) layer on the surface of ferrous metals. Here are the general steps involved, incorporating information from the previous content and common practices. Remember that specific procedures can vary depending on the type of black oxide process (hot, mid-temperature, or cold) and the material being treated. Always consult best practices and safety data sheets for the specific chemicals used.I. Pre-Treatment and Cleaning:

II. Black Oxide Conversion Coating:

III. Post-Treatment and Sealing:

Types of Black Oxide Coating

The hot black oxide coating is the most commonly used type, involving immersion of parts in a boiling bath of alkaline salts, nitrites, and nitrates at a temperature of 285-305°F. This process produces a thick, durable coating of black iron oxide (Fe3O4) that is highly resistant to corrosion and enhances the beauty of the metal surface. The hot blackening method is often employed in tools, weaponry, and mechanical parts that require high corrosion resistance.

The mid-temperature black oxide process is carried out at a temperature of around 100-120°C, making it a more energy-efficient and environmentally friendly option. This process is suitable for stainless steel, carbon steel, and some non-ferrous metals, and produces a coating that is equally effective as the hot black oxide process. The mid-temperature process is frequently used in mass-produced machinery and home appliance parts, and has the advantages of requiring little manpower and working well on large-scale manufacturing lines.

The cold black oxide process is a quick and safe method that is performed at ambient temperature, making it suitable for metal parts that cannot withstand high-temperature processing. This process involves depositing a thin coating of black oxide film on the metal surface, which provides some cosmetic and corrosion-prevention benefits. The cold black oxide process is particularly suitable for small metal parts, electronic components, and decorative hardware that require rapid processing.

| Characteristic | Hot Black Oxide | Mid-Temperature Black Oxide | Cold Black Oxide |

|---|---|---|---|

| Temperature | 285-305°F | 200°F | Room temperature |

| Process | Immersion in boiling bath of alkaline salts, nitrites, and nitrates | Immersion in a more comfortable temperature | Immersion in a chemically aggressive bath |

| Coating Characteristics | Smooth, even, black, durable, and resistant to corrosion | Smooth, even, black, durable, and resistant to corrosion | Thin, black oxide film, not as durable or resistant to corrosion |

| Suitable Materials | Iron, steel | Stainless steel, carbon steel, non-ferrous metals | Metal parts that cannot withstand high-temperature processing |

| Applications | Tools, weaponry, mechanical parts | Home appliances, fasteners, automobile parts | Small metal parts, electronic components, decorative hardware |

| Advantages | High corrosion resistance, beautiful finish | Energy-efficient, less waste, comfortable temperature | Quick, easy, safe, suitable for small parts |

| Disadvantages | High energy consumption, requires specialized equipment | Not as durable or resistant to corrosion as hot black oxide | Not as durable or resistant to corrosion as hot or mid-temperature black oxide |

Related News

FAQs

Is black oxide corrosion-resistant?

Black oxide is a chemical conversion coating applied to ferrous metals, primarily to enhance their aesthetic appeal and provide some level of corrosion resistance. However, its corrosion resistance is limited and depends on several factors.

Black oxide coatings provide only minimal corrosion resistance on their own. The coating is essentially a layer of magnetite (Fe3O4), which is a stable form of iron oxide, but it does not prevent rusting effectively in humid or wet environments.

To enhance corrosion resistance, black oxide finishes are often treated with a post-coating sealant, such as oil or wax. This additional layer can significantly improve the coating’s ability to withstand moisture and humidity, potentially offering protection for up to 100 hours in high humidity conditions.

What is the difference between zinc plating and blackening (black oxide)?

● Composition and Process

Zinc Plating: This is an electroplating process where a layer of zinc is deposited onto the surface of a metal part. The thickness of the zinc coating typically ranges from 0.0002 to 0.0006 inches (about 5 to 15 micrometers) and can be followed by a chromate conversion coating to enhance corrosion resistance and provide a black appearance, known as black zinc plating.

Black Oxide: This is a chemical conversion process that creates a very thin layer of magnetite (Fe3O4) on the surface of steel parts. The thickness of the black oxide layer is extremely minimal, usually just a few millionths of an inch (approximately 3 micrometers). This process does not add significant thickness to the part.

● Corrosion Resistance

Zinc Plating: Offers superior corrosion protection due to the sacrificial nature of zinc. If the coating is scratched, the zinc will corrode before the underlying steel, thereby protecting it from rust. Black zinc plating enhances this property further by providing a protective layer that is more resistant to corrosion than standard zinc plating alone.

Black Oxide: Provides minimal corrosion resistance. The protection mainly comes from an oil or wax that is applied after the black oxide process. Without this protective layer, black oxide parts can rust quickly when exposed to moisture.

● Appearance and Aesthetic Qualities

Zinc Plating: Typically has a shiny, metallic finish, which can be altered to a matte black finish through the use of black chromate. This finish is often more visually appealing for decorative applications.

Black Oxide: Produces a flat black finish that is often preferred for aesthetic reasons in applications where glare reduction is important, such as in firearms and precision instruments.

● Applications

Zinc Plating: Commonly used in automotive, construction, and manufacturing industries for parts that require corrosion resistance and a durable finish. It is suitable for a wide range of applications, including fasteners and structural components.

Black Oxide: Often used in applications where minimal dimensional change is critical, such as in precision machined parts, gears, and tools. It is also favored in applications where a non-reflective surface is desired.

● Impact on Dimensions

Zinc Plating: Adds a measurable thickness to the part, which can affect tolerances in precision applications. This is particularly important in parts that require tight fits.

Black Oxide: Has negligible impact on dimensions, making it suitable for applications where maintaining tight tolerances is essential.

How long does black oxide coating last?

Black oxide coatings are known for their durability and can last for several years without showing significant signs of wear or deterioration. Typically applied to steel at a thickness of about 0.001 inches, these coatings provide effective protection against rust, enhancing the longevity of treated metal surfaces. However, factors such as environmental conditions and maintenance practices can influence their lifespan; for instance, coatings generally last longer in indoor environments compared to outdoor settings, where humidity and temperature fluctuations can accelerate wear. Additionally, proper application and the use of after-finishes like oil or wax can further enhance corrosion resistance.

Is black oxide coating expensive?

Black oxide coating is generally considered a low-cost finishing method compared to other protective coatings. It is often used to enhance the appearance of parts, reduce reflection, and provide some level of corrosion resistance, particularly for ferrous metals. While it is more affordable than options like zinc plating or powder coating, it’s important to note that black oxide does not offer the same level of corrosion protection, and its durability is also less than that of many other finishes.

Which materials are suitable for black oxide treatment?

Black oxide coating is primarily designed for and most effectively used on ferrous metals, with steel being the most commonly treated material. Both carbon and alloy steel varieties respond exceptionally well to this coating process, resulting in a uniform and durable protective layer that enhances corrosion resistance and aesthetic appeal. Stainless steel can also be successfully treated with black oxide, though it requires a specific pre-treatment to ensure proper coating adhesion, while cast iron’s high carbon content makes it another suitable candidate for this treatment, offering improved protection against rust and a refined finish. Although black oxide coating is mainly associated with ferrous metals, certain non-ferrous metals like copper, brass, and aluminum can achieve similar blackened appearances through specialized alternative processes, such as black anodizing for aluminum, though these methods differ from traditional black oxide treatment in their chemical and procedural approaches.