ABS Plastic in CNC Turning – CNC Turning ABS

ABS plastic is a terpolymer of acrylonitrile (A), butadiene (B), and styrene (S). It has common properties of these three components, such as good surface hardness, chemical corrosion resistance, heat resistance, high elastic and high toughness, and good machinability, which makes ABS is suitable in Precision CNC Turning. CNC machine tools working with ABS workpiece, go through the operations instructed by computers, complete the materials removal, to get the final ABS parts. CNC Turning ABS parts are widely used in automobile, chemical, machinery, electrical, textile, aircraft, ship and other manufacturing industries. The changes of the relative content of the three monomers in ABS polymer will form different types of plastics, further makes ABS CNC turned parts with varying performance.

ABS CNC Turning Services – CNC Turning ABS Parts & Components Manufacturer

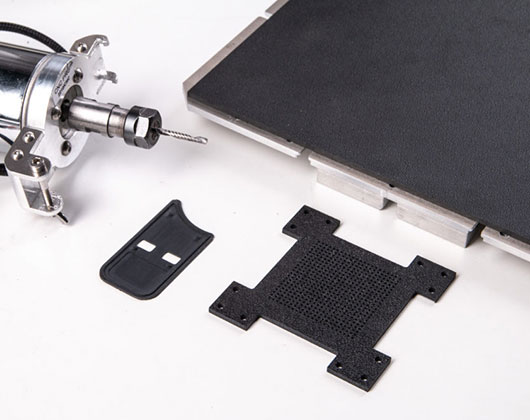

CNClathing.com is comprehensive CNC machining services China top provider, we are always specialized in CNC machining, CNC turning, CNC drilling, CNC milling in a range of metal and plastic materials. Focusing on high precision, exact specification and high durability, our professional engineering team, skilled machines operator, and CNC turning center are capable to complete the ABS CNC turning process efficiently. Our CNC turned ABS parts are manufactured with the highest industry standards and premium quality, custom ABS components project will be carried out according to your requirements as long as parts drawings and details are provided. Our capability for diameter of ABS turning parts is from 1mm to 300mm.