Precision Custom CNC Parts Machining & Manufacturing – OEM CNC Parts Supply Online

JUNYING precision CNC machining services are ideal for manufacturing custom CNC parts & components needed for customers across a wide variety of industries and specialty applications, such as aerospace, medical, automotive, electronics, and industrial machinery. Junying is a CNC machined parts online supplier providing top-quality OEM CNC metal & plastic parts made of other materials. CNC components machining service at Junying can work with stainless steel, carbon steel, brass, aluminum, titanium, bronze, plastics, etc. Our global custom machining network is optimized for production in flexible quantities. In addition to conventional turning, milling, and drilling processes, we also offer a ton of other sheet metal fabrication and rapid prototyping services to take your unique design to realization with the help of professional engineers and seasoned workers. Our team can provide different custom metal finishing services for your CNC machining parts, such as anodizing and electro galvanizing. If you need, our certified partners can provide forging, extrusion, heat treating, and other operations. The comprehensive services make us a one-stop shop that provides the best quality control and competitive price. With our advanced CNC machining capabilities, we manufacture OEM CNC parts with tight tolerances and superior surface finishes, whether you need metal lathe parts, CNC metal & plastic parts, or high-precision machining parts.

Upload your CAD file today to get an instant quote for CNC parts online!

Why Choose Junying CNC for Custom Parts?

-

Cutting-Edge CNC Technology & Smart Quoting System

Unlike traditional CNC manufacturers, we use AI-driven quoting algorithms to provide real-time price estimates based on material selection, machining complexity, and production volume. -

Ultra-Precision Machining (±0.001mm Tolerances)

Our 5-axis CNC machines and Swiss-type lathes allow us to achieve tight tolerances, making us a top choice for aerospace, medical, and high-tech industries. -

Diverse Material Capabilities

We offer CNC machining for metals (aluminum, titanium, stainless steel, brass, copper) and plastics (ABS, PEEK, Nylon, Polycarbonate), as well as high-performance alloys like Inconel and Hastelloy. -

Hybrid Manufacturing: CNC + 3D Printing + Investment Casting

We integrate CNC machining, 3D printing, and investment casting to provide cost-effective solutions for prototyping and complex part production. -

100% Quality Guarantee with CMM Inspection

Every part undergoes multi-stage inspections using CMM (Coordinate Measuring Machines), laser scanning, and digital microscopy to ensure dimensional accuracy and surface quality. -

Sustainable CNC Manufacturing

Our eco-friendly machining methods reduce material waste by up to 30%, and we prioritize recyclable materials and energy-efficient production processes.

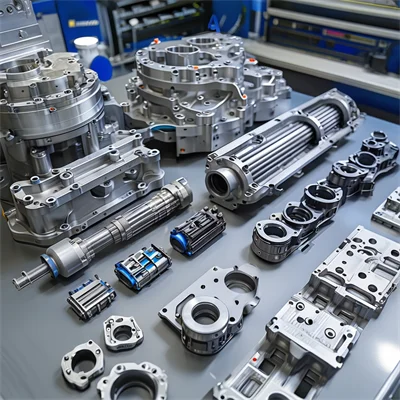

Comprehensive Precision CNC Part Manufacturing Services

We offer a full range of CNC machining services to meet your specific manufacturing needs:

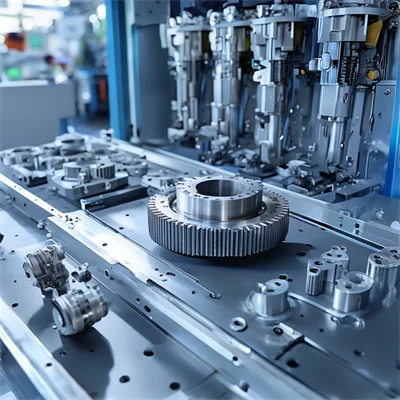

1. CNC Turning & Milling Services

- High-precision CNC lathe machining for cylindrical components

- Multi-axis CNC milling for complex geometries

- Suitable for rapid prototyping & mass production

2. CNC Drilling & EDM Machining

- CNC drilling for high-accuracy hole-making

- Wire EDM & sinker EDM for intricate details

- Ideal for high-performance industries

3. Sheet Metal Fabrication & 3D Printing

- Sheet metal cutting, bending, and welding

- Rapid prototyping using 3D printing for quick iterations

- Suitable for custom enclosures, brackets, and precision components

4. Custom Metal & Plastic CNC Machining

We provide custom machining for a variety of materials, ensuring optimal strength, durability, and cost efficiency.

Metal CNC Machining

- Aluminum CNC Machining – Lightweight, corrosion-resistant, ideal for aerospace & automotive

- Stainless Steel CNC Machining – High strength, wear-resistant, perfect for medical & industrial applications

- Brass & Copper CNC Machining – Excellent conductivity, widely used in electronics

- Titanium CNC Machining – High-strength, lightweight, used in aerospace & medical industries

Plastic CNC Machining

- ABS CNC Machining – Durable and impact-resistant

- Nylon CNC Machining – High wear resistance, suitable for gears & bushings

- PEEK CNC Machining – High-temperature resistance, used in medical & aerospace applications

- Polycarbonate CNC Machining – Transparent and strong, ideal for optical components

What is Custom Machining?

Custom machining often refers to custom CNC machining services provided to meet the specific requirements of customers for piece-parts, or component parts. Most of the custom machined parts are made with CNC machines. With the development of manufacturing techniques, design software, transportation, and shipment, custom parts for specific uses are becoming more and more common among CNC machining parts orders. Custom CNC machining uses CAD files and converts them to the programmed languages for instructing the actions of machines. Generally, the customer’s requirements are specified by a detailed 2D/3D drawing with additional notes or markings. Custom machining involves various forms of technologies and machinery, from traditional lathes to 5-axis CNC machining centers to Swiss-type machines, and from rapid prototype to plastic machining to metal machining. Normally, CNC milling and CNC turning can implement a lot of features. But some custom machining jobs do not require CNC equipment at all.

When and Why Custom Machining is Needed?

In some cases, when designers create a new production project, and a single component of the product cannot be purchased from the supplier or not sold at a reasonable price, custom machining is required. Completely ordinary parts that happen to have special requirements may also need custom machining. These components may be simple or just new inventions, such as gears of non-standard sizes or materials, custom adapters, text engraving, etc. When the part is not sold as an off-the-shelf item or catalog, custom machining is needed to customize it. Depending on the shape, size, and other requirements of the custom machined parts, the production might be done using a lathe, a milling machine, a drill bit, a stamping press or other equipment. Quality CNC custom parts can be made in high efficiency from their digital files because there is rarely a minimum order quantity and the setup time is short.

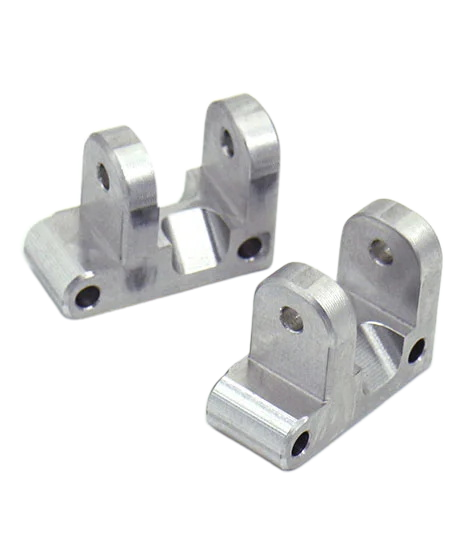

Characteristics of Custom CNC Parts

Custom CNC parts manufacturing offers superior performance and flexibility compared to standard components.

-

High Strength & Durability

Custom CNC machining components are engineered for demanding applications, ensuring high integrity and performance.

-

Superior Precision & Accuracy

We achieve tight tolerances down to ±0.001mm, making us a leader in precision CNC parts manufacturing.

-

Fast Production & Prototyping

Our CNC machining services ensure rapid production of machined parts, ideal for fast turnaround needs.

-

Custom Features Not Available in Standard Parts

CNC milling & turning allows for unique geometries, coatings, and material options.

-

Low-Volume & High-Mix Flexibility

We support both small-batch and large-scale CNC parts manufacturing.

-

Assembly-Ready Components

Multiple custom CNC machining components can be assembled into a complete system.

Looking for high-precision CNC parts online? Get an instant quote today!

Industries We Serve with Custom CNC Parts

Aerospace & Defense

Lightweight aluminum and titanium aircraft components.

Custom aerospace brackets, turbine blades, and satellite parts.

Medical & Healthcare

Titanium surgical implants, orthopedic devices, and prosthetic components.

ISO 13485-compliant medical machining for high-precision parts.

Automotive & Motorsport

Custom engine parts, transmission components, and racing-grade CNC machining components.

Electronics & Semiconductor

Custom CNC heat sinks, PCB enclosures, and micro-precision connectors.

Industrial Machinery & Robotics

High-strength gears, shafts, brackets, and automation system CNC machining components.