3D printing is the most popular rapid prototyping process, 3D printing rapid prototyping service only takes a short time to make the final parts, with high design freedom and suitable for low volume production due to affordability. Our 3D printing services including including FDM, SLA, SLS, SLM, etc. can be used to support a variety of prototyping processes to produce plastics, silicone, or rubber parts, composites, and even metal parts. Now we the 3D priting techniques for prototyping, choose the best one depends on the type of materials and requirements:

SLA (Stereolithography)

SLS (Selective Laser Sintering)

MJF (Multi-Jet Fusion)

DMLS (Direct Metal Laser Sintering)

FDM (Fused Deposition Modeling)

PolyJet (PJET)

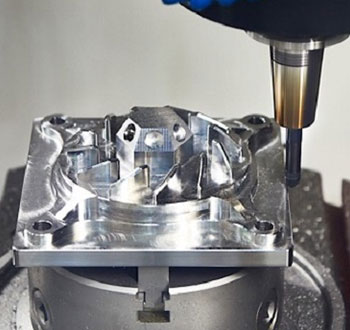

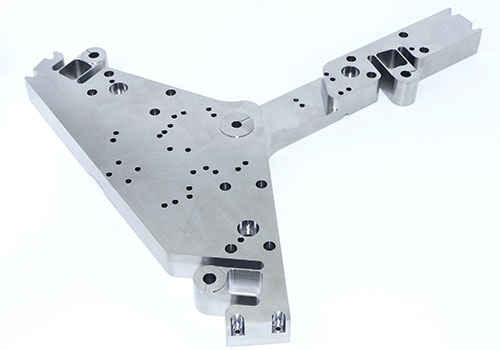

CNC prototype machining offers a variety of material (metal, plastic, composites, etc.) and finishing options, and can be combined with other types of prototyping services. Therefore, CNC machining is a versatile prototyping method that can not only machine simple parts at high speed, but also professionally produce complex prototype parts with high precision. The rapid prototyping of CNC machined parts is realized by CNC machine tools such as lathes, mills, and CNC machining centers, required the one depending your demand:

CNC Turning

CNC Milling

CNC Drilling

CNC Cutting

Sheet Metal Fabrication

Rapid injection molding allows us to manufacture prototype injection molded parts for full functional purposes or fit testing, is a great prototyping method for fast and economical production of large quantities. Prototype molding can be built quickly, and the part has the shape and functions a plastic prototype needs for testing, fitting, and work. Most colors and materials are available. With our custom rapid molding service, you can tailor prototypes or molds to meet unique requirements, allows you to try different custom shapes, designs, and finishes, enabling you to design parts with complex geometries. For meeting worldwide client’s needs, we offer the comprehensive rapid molding technologies for different mats and specifications:

Injection Mold (Plastic Mold)

Compression Molding (Plastic Mold, Rubber Mold)

Blow Molding (Plastic Mold)

Transfer Molding (Resin Mold)

Die Casting Molding (Aluminum Mold, Zinc Mold)

Extrusion Molding (Plastic Mold)

Rotational Molding (Plastic Mold)

Vacuum casting is an excellent, rapid, and economical prototyping solution for your low-volume plastic parts or high-quality mold production. By working on the silicone master model made via 3D printing or CNC machining, vacuum casting creates a high-precision prototype with the texture and complex structural features of the masterpiece. It also allows us to modulate colors on transparent materials and verify the compatibility of different materials. So you can use our following vacuum casting services for making visual models, functional prototypes, pre-production parts, and many more:

Polyurethane Vacuum Casting

Silicone Rubber Vacuum Casting

Wax Vacuum Casting

Metal Vacuum Casting

Resin Vacuum Casting

Reverse engineering for rapid prototyping is primarily used to replicate a product more inexpensively or because the original part is no longer available; it can also help improve your product quality! By using reverse engineering, a 3D physical product can be quickly captured in digital form, remodeled, and exported for rapid prototyping or rapid manufacturing using multi-axis CNC machining techniques! Our reverse engineering techniques and secondary design service can assist manufacturers and designers in meeting the demands of shortened product development time. Our reverse engineering for prototyping covering:

Recreating Legacy Parts

Product Improvement

Design for Manufacturability (DFM)

Rapid Testing of Variants

Fast iteration and customization