CNC Stainless Steel Machining Services and Parts

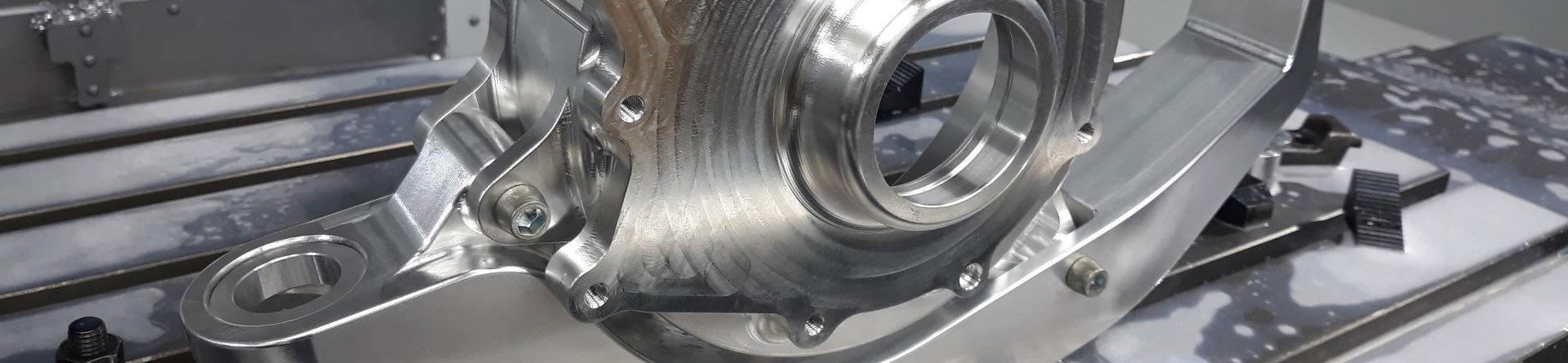

If you are seeking a professional CNC machining supplier to provide high quality precision CNC machined stainless steel parts, CNCLATHING is one of the most affordable and capable manufacturer, specializing in stainless steel CNC machining services with advanced 3-axis and 5-axis CNC machines. Our professional technical team has in-depth understanding of special stainless steel CNC machining requirements (custom CNC stainless steel turning, CNC stainless steel milling, CNC stainless steel drilling, stainless steel prototyping), and state-of-the art facility has helped us achieve this distinction. With great experience and broad knowledge, our CNC stainless steel machining center can reach extremely tight tolerances in manufacturing CNC steel machined parts & products.

Precision CNC machined stainless steel parts are becoming a choice for many industries due to their desirable physical properties! Stainless Steel is one of the most popular industrial alloys for many CNC machining projects, due to its excellent physical properties. The following benefits have made Stainless Steel parts and products a viable choice for many industries and applications, though they are particularly favored in the medical, automotive, aerospace, healthcare, and consumer electronics spheres. While the best and fastest way to make stainless steel parts is CNC machining, especially CNC milling with stainless steel reaches far and wide.

Advantages of CNC Machining in Stainless Steel

- Great precision and high tolerance ensure high-quality stainless steel parts

- Time and cost-saving, great speed of CNC Machining Stainless Steel part

- Allows products ordered to be made precisely to the specifications stated

- Complex stainless steel parts for high tech industry can be machined

- Consistent repeatability guarantees uniformity in large production runs

- Ability to handle hard-to-machine stainless steel grades with advanced tooling

- Efficient use of materials minimizes waste and supports sustainable manufacturing

- Improved safety by minimizing direct human contact with sharp tools and heavy equipment

- Enhanced surface finishes reduce or eliminate the need for secondary operations

CNCLATHING.COM: Stainless Steel CNC Machining Services and Components Supplier

Junying Metal Manufacturing Inc. is one of the reliable precision CNC machined stainless steel parts manufacturer in the China. Our years professional CNC Stainless Steel Machining center provide you all-around care services that our experienced project engineers and machinists will analyze your project carefully and process it with the most efficient process of machined aluminum to to meet your design specification, while optimize your time and cost.

Specification of Our Stainless Steel CNC Machining Services

What Is Stainless Steel and Can It Be Machined?

Stainless steel is an alloy made mainly from iron mixed with at least 11% chromium, which helps it resist rust and damage. Sometimes, other elements like carbon, nickel, or molybdenum are added to give it extra strength or toughness. Because of its unique mix, stainless steel stays strong and shiny even after years of use. It can definitely be machined, meaning it can be cut, shaped, or drilled into parts using CNC machines. Different types of stainless steel have different levels of machinability. For example, some grades like 304 are easier to work with than others like 316. Knowing the right tools and speeds helps make machining stainless steel easier and more efficient.

Main Properties of Stainless Steel

✅ Corrosion Resistance

The primary advantage of stainless steel is its ability to withstand corrosion. The chromium content reacts with oxygen to create a stable, passive film on the metal’s surface. This layer shields the underlying metal from rust and can self-repair if damaged, maintaining the material’s integrity over time.

✅ Mechanical Strength

Stainless steel exhibits high tensile strength and durability. Standard grades like 304 stainless steel have yield strengths around 210 MPa, which can be significantly increased through cold working or heat treatment. Specialty alloys such as precipitation-hardening steels can achieve yield strengths exceeding 1,700 MPa.

✅ Melting Point

With melting temperatures ranging from approximately 1,325°C to 1,530°C, stainless steel can endure extremely high heat without melting or losing structural stability, a property that benefits industries exposed to elevated temperatures.

✅ Electrical Conductivity

Stainless steel is a relatively poor conductor of electricity compared to materials like copper due to its dense oxide surface layer. While this limits its use in electrical connectors, it remains valuable in environments where corrosion resistance is essential.

✅ Magnetic Properties

Certain stainless steel families, such as ferritic and martensitic types, exhibit magnetic behavior because of their crystal structure. Austenitic stainless steels, however, are generally non-magnetic unless mechanically stressed or deformed, which can induce slight magnetism.

✅ Wear Resistance

Although stainless steel resists abrasion and surface damage well, it can experience galling—a form of adhesive wear where materials stick and tear when sliding under high pressure. This can be minimized by using dissimilar metals or applying lubricants during assembly.

✅ Density

The density of stainless steel typically ranges between 7.5 and 8.0 grams per cubic centimeter, contributing to its robust and sturdy nature.

✅ Fire Resistance

Stainless steel performs exceptionally well under fire exposure, maintaining structural stability at temperatures above 800°C. It also has a low emission of toxic fumes when exposed to fire, making it a safe choice for building and industrial applications.

✅ Aesthetic Appeal

Stainless steel offers a wide variety of surface finishes, from matte to highly polished, and can be textured or tinted. This versatility makes it a preferred material in architectural design, interior décor, and consumer goods for its clean, modern appearance.

Types of Stainless Steels for CNC Machining

Austenitic Stainless Steel

Austenitic stainless steels are the most popular type for CNC machining services. Known for their excellent formability, weldability, and corrosion resistance, these steels contain high levels of chromium and nickel, making them non-magnetic and very tough. Common grades include 304 and 316. Grade 304 is widely used thanks to its versatility, while 316 contains molybdenum for extra corrosion resistance, especially in marine environments. Although they are harder to machine due to work hardening, their excellent durability makes them ideal for food processing, medical devices, and chemical equipment.

Martensitic Stainless Steel

Named after Adolf Martens, martensitic stainless steels are famous for their high hardness and strength. They can be heat-treated to achieve very high toughness and produce mechanical parts. Examples include grades like X12Cr13 (AISI 410) and X50CrMoV15. These steels often contain higher carbon levels and are magnetic. Martensitic steels are commonly used for surgical tools, cutlery, and automotive parts where strength and wear resistance are critical. Another typical example is SS416, which is a free-machining material, easier and faster to machine than most martensitic steels, and is often used where good corrosion resistance with easy machining is needed.

Ferritic Stainless Steel

Ferritic stainless steels belong to the AISI 400 series and are magnetic with excellent resistance to stress corrosion cracking. These SS grades are not heat-treatable but offer good corrosion resistance, especially in less aggressive environments. Common alloys include 430 and 409L. They are often used in automotive parts, kitchenware, and industrial tools. Their machinability is moderate, and they are less ductile than austenitic grades.

Duplex Stainless Steel

Duplex stainless steels combine the best features of austenitic and ferritic steels, offering a balanced microstructure of both. This results in high strength, good corrosion resistance (especially stress corrosion cracking), and improved toughness. There are standard, super, and lean duplex grades like X2CrNiN22-2. These steels are popular in chemical plants, marine applications, and heat exchangers due to their durability and resistance to harsh conditions.

Precipitation-Hardening Stainless Steel

Precipitation-hardening (PH) stainless steels contain small amounts of elements like titanium or copper that allow them to be heat-treated to very high strengths. One common grade is 17-4 PH. This type is great when high strength and moderate corrosion resistance are needed, such as in aerospace, nuclear, and marine industries. Machining PH steels requires careful tool selection and cooling due to their hardness.

Common Stainless Steel CNC Machining Grades

| Stainless Steel Grade | Material Properties | Machining Process | Applications | Cost | Machining Tips |

|---|---|---|---|---|---|

| 303(Austenitic) | Excellent machinability due to added sulfur; good toughness; moderate corrosion resistance | CNC Milling, CNC Turning | High-volume production parts, fast machining components | Moderate | Use higher cutting speeds; expect shorter tool wear; sulfur improves chip breaking |

| 304(Austenitic) | Great corrosion resistance; good formability and weldability; moderate machinability | CNC Milling, CNC Turning | Food processing, kitchen equipment, medical devices | Moderate | Work hardens rapidly; use sharp tools and proper coolant to avoid tool wear |

| 316(Austenitic) | Superior corrosion resistance (especially chloride environments); contains molybdenum; more difficult to machine | CNC Milling, CNC Turning (slower speeds) | Marine, chemical processing, pharmaceutical equipment | High | Use slower cutting speeds; specialized tooling needed; heavy coolant recommended |

| 416(Martensitic) | High machinability due to added sulfur; good corrosion resistance; magnetic; moderate hardness | CNC Milling, CNC Turning | Shafts, valves, fasteners, pump parts | Moderate | Easy to machine; use sharp tools; watch for heat buildup; good for parts requiring good surface finish |

| 420(Martensitic) | High hardness after heat treatment; magnetic; moderate corrosion resistance; can be polished to a high shine | CNC Milling, CNC Turning | Cutlery, surgical instruments, scissors | Moderate to High | Requires sharp tooling; slower feed rates to prevent chipping; heat treat after machining for max hardness |

| 440C(Martensitic) | Very high hardness and wear resistance after heat treatment; magnetic; moderate corrosion resistance | CNC Milling, CNC Turning | Bearings, knives, high-wear parts | High | Difficult to machine due to hardness; use carbide tools; slow speeds and heavy coolant essential |

| 430(Ferritic) | Magnetic; good corrosion resistance; moderate toughness; not heat treatable | CNC Milling, CNC Turning | Automotive parts, kitchenware, industrial tools | Low to Moderate | Moderate machinability; avoid overheating; less ductile than austenitic |

| 17-4 PH(Precipitation Hardening) | Very high strength after heat treatment; moderate corrosion resistance; magnetic | CNC Milling, CNC Turning (rigid setups) | Aerospace, nuclear, marine, high-strength parts | High | Use sharp carbide tools; maintain rigid setups; heavy coolant; machine in solution treated condition if possible |

| 201(Austenitic) | Lower nickel content; good corrosion and chemical resistance; moderate machinability | CNC Milling, CNC Turning | Household appliances, automotive parts | Low to Moderate | Similar handling as 304; watch for work hardening |