Custom Sheet Metal Fabrication & Cutting Services – Rapid Sheet Metal Prototyping Company China

If you want to find a cost-effective and rapid sheet metal prototyping solution for your manufacturing needs, Junying can be a good choice for you. Based on extensive experiences and professional expertise, our sheet metal fabrication services are available for both prototypes and low to high-volume production runs. Working with Junying, the most advanced fabrication machinery allows us to fabricate end-use sheet metal parts and cut various materials with high efficiency while maintaining premium quality, which saves money and time for our clients significantly. A wide range of materials and surface finishes enable us to make the best option for your project, the raw materials include but are not limited to stainless steel, aluminum, brass, copper, steel, plastic, etc. Polishing, painting, sandblasting, plating, anodizing, powder coating, and other finishing services bring better surface quality to your parts. Our custom sheet metal fabrication service provides durable and affordable sheet metal components that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Sheet materials or stock are usually cut using a high-powered CNC laser or waterjet. Our CNC cutting services can cut an extensive range of materials using laser cutting, waterjet, and other technologies. According to your requirements and applications, we’ll offer suggestions for product design, suitable materials, and the most cost-effective methods for sheet cutting. Minimal cost, time, and best quality are our purposes. Equipped with state-of-the-art facilities and measuring equipment in our factory, CNC metal, and plastic cutting now supplies CNC cutting parts for a number of business sectors and private individuals, catering to both long and short production runs. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.

Why Choose Custom Sheet Metal Fabrication & Cutting Services at Junying?

- Capabilities in fabrication, machining and finishing enable us to offer one-stop shopping

- Sheet metal fabrication service supplies durable parts for prototype and end-use

- A wide selection of material and surface metal finishing or treatment processes

- Accurate dimensions and specifications based on your demands and a variety of instruments

- Quick free quote within 24 hours and fast turnaround in average one week

- Competitive prices and the highest standard quality provide the most economic solution

- No minimum order quality. You can order a prototype of thousands of metal parts

Sheet Metal Materials

Sheet metal is a widely used form of raw material, usually 0.006 and 0.25 inches thick sheet used in sheet metal fabrication. Use the sheet metal gauge chart on our site to designate the thickness. Here are some popular sheet metal materials, stainless steel grade 304 is one of the most common options due to its good corrosion resistance, formability and weldability. If your applications are pumps, valves, chemical equipment, and marine product, grade 316 is recommended. For aluminum, the four most common aluminum grades available as sheet metal are 1100-H14, 3003-H14, 5052-H32, and 6061-T6. Brass is also widely used in the sheet metal fabrication process, it has more strength, corrosion resistance, and formability when compared to copper while retaining its conductivity.

- Aluminum: Al 5052, 6061

- Copper: C101, C110, brass (C260)

- Stainless Steel: SS 301, 304, 316/316L

- Steel: low carbon steel

Types of Sheet Metal Finishes

If you require special treatment or post-processing for your parts, please check out the following sheet metal finishing options. If you can’t find what you want, welcome to send your inquiry to us, a wide range of surface finishes are available at Junying, a fast quote will be offered. Custom materials finish making your sheet metal fabricated parts achieve improved appearance and performance.

- Bead Blast

- Anodize

- Plating (Nickel Plating, Silver Plating, etc.)

- Powder Coating

- Chromate Conversion Coating

- Custom finishing services

Sheet Metal Fabrication Sizes & Tolerances

1.Dimensions of sheet metal fabrication parts

Size: 47 in. x 119 in. OR 1,193.8mm x 3,022.6mm (max)

Bend length: 10 ft. OR 3.048m (max)

Flat part: 0.5 in. x 0.5 in. OR 12.7mm x 12.7mm(min)

Formed part: 1.5 in. x 1.5 in. OR 38.1mm x 38.1mm (min)

2.Sheet metal fabrication tolerances of different features for reference.

Bends: +/- 2 degree

Offsets: +/- 0.024 in. (+/- 0.608mm)

Hole Diameters: +/- 0.010 in. (+/- 0.254mm)

Edge to Edge/Hole; Hole to Hole: +/- 0.010 in. (+/- 0.254mm)

Hardware to Edge/Hole:+/- 0.020 in. (+/- 0.508mm)

Hardware to Hardware: +/- 0.030 in. (+/- 0.762mm)

Bend to Edge: +/- 0.020 in. (+/- 0.508mm)

Bend to Hole/Hardware/Bend: +/- 0.030 in. (+/- 0.762mm)

Features Separated By Two or More Bends: +/- 0.060 in. (+/- 1.524mm)

What is Sheet Metal Fabrication?

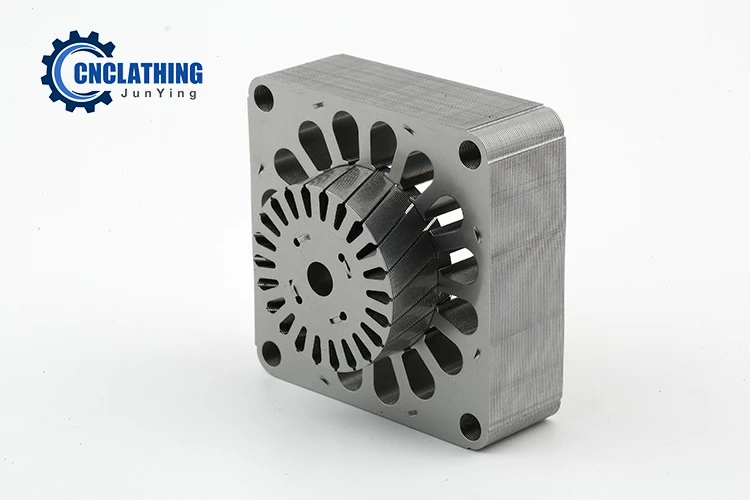

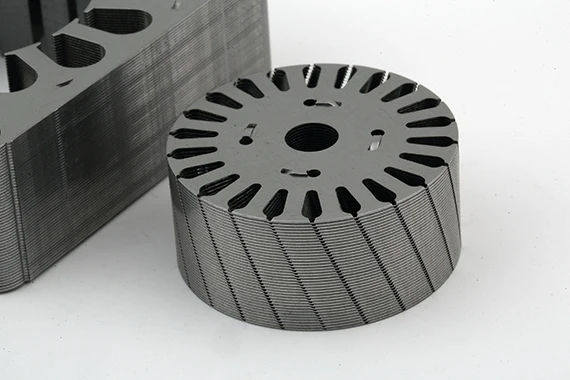

Sheet metal fabrication involves a set of manufacturing processes of forming either prototypes or end-use parts from sheet metal. Cutting, bending and punching are commonly used. So typical tools used in sheet metal fabrication including brakes, punches and dies. The type of machine used depending on the material, the gauge of the sheet, and other factors. Most sheet metal components require a combination of forming processes, but this will not increase the price greatly. The 3D CAD design will be converted into a special machine code, which controls the machine to execute cutting operation precisely and fabricate the final part. Sheet metal parts are known for their durability and economics, which makes them the perfect choice for lots of end-use applications.

How Does Sheet Metal Fabrication Work?

The common sheet metal fabrication process starts with material removal, during the stage, the raw material is cut to the desired shape by different cutting tools. A variety of subtractive machining processes can complete the operation. The second stage of sheet metal fabrication is material deformation. The piece that has been cut needs to be formed into a 3D shape with the forming process like bending. No materials are removed during the stage. The last step is to assembly several pieces into a complete product if there are multiple parts. Sometimes, surface treatment is needed to provide a better surface finish.

What is a Sheet Metal Prototype?

A sheet metal prototype is an early sample, model, or release of a metallic product used to test a concept or process. Rapid sheet metal prototyping service develop prototypes based on designs submitted by customers and test the product before it enters the market. This can minimize the loss and reduce the risk. Various sheet metal prototyping processes at Junying can design your orders in hours and suit your varying needs.

Advantages of Sheet Metal Fabrication

- High malleability and durability to withstand pressures and last a long time

- Reduced tooling time to cut or bend the metal, save on the production cost

- Easy to handle custom simple or complex projects, whether prototypes or large scale

- Standard sheet metal thickness used in laser cutting or bending

- Inexpensive but high-quality end-use sheet metal products

- Improved construction quality, easier to maintain

- Sheet metals can be formed into virtually any desired shape

- Sheet metal parts are recyclable and not harmful to the environment

- High strength and high resistance to corrosion, sun, and moisture

What are Sheet Cutting & CNC Cutting?

Unlike traditional cutting services, CNC cutting is a subtractive manufacturing method that uses a variety of different cutting technologies combined with computer numerical control software to remove excess materials from the block and create specific 2D or 3D shapes. Sheet cutting refers to the process in which the materials are sliced into flat forms following a profile. Common CNC cutting machines and sheet cutting tools include laser, water jet, route, plasma, knife, etc. CNC cutting services provide products for aerospace, automotive, chemical, agriculture, military, defense, and commercial and industrial applications. Sheet cutting is widely applied due to its speed, precision, and accuracy, as well as little human error. CNC cutting process can be performed alone or with other processes depending on the configuration and purposes.

Types of Sheet Cutting – CNC Cutting Technologies & Processes

– Plasma Cutting: a plasma cutting torch is usually used to cut through various materials such as stainless steel, mild steel, aluminum, brass, etc., ideal for budget rapid prototyping, large pieces, extended jobs, and more. It is the most affordable cutting option.

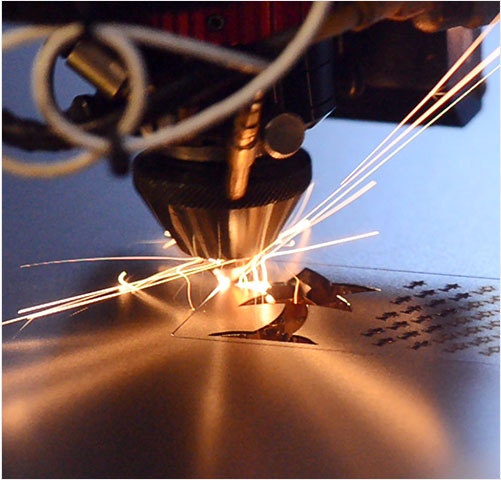

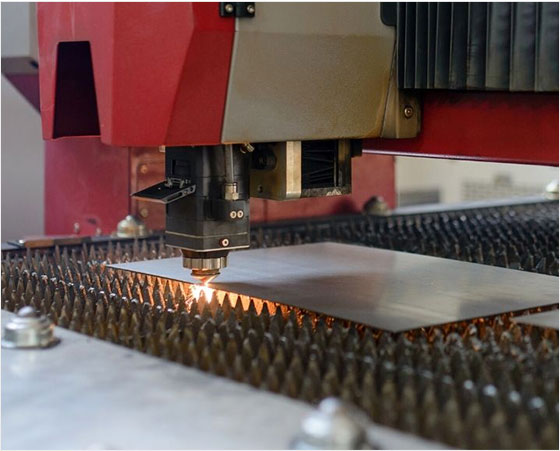

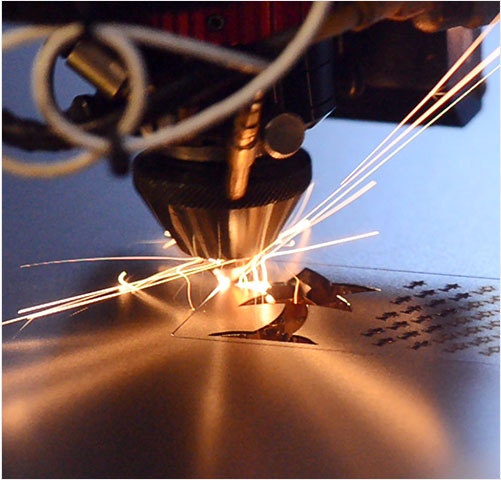

– Laser Cutting: a manufacturing process carried out by CNC laser cutters, lasers can cut a number of materials, even cutting through the toughest metals and hardest gemstones with efficiency. It is also an extremely quick process to cut wood and plastic materials to create excellent cut-edge quality and an exceptional level of detail. Laser cutting can produce intricate parts to high tolerances with a smooth surface finish.

– Waterjet Cutting: this process uses an ultra-high pressure stream of water to carry abrasive grit, which leaves a precise and smooth cut surface on the workpiece. Water jet cutting is the most versatile method to cut almost any material with good surface quality and no heat-affected zone, but it is less efficiently compared to the other two cutting techniques.

CNC Cutting vs Laser Cutting, What’s the Difference?

CNC cutting uses Computer Numerical Control devices and specialized tools to produce final parts based on the CAD design or drawing provided by clients. The design will be converted to instructions to the CNC machine, then guide the operations of tools. Laser cutting also applies a CNC system to quite the laser cutting machine, which relies on heat to shape the workpiece. A high-energy light beam is used to burn through the metal material to get desired geometries.

What’s the difference between CNC cutting and laser cutting? The major difference between them is how the cutting is performed. A CNC cutting machine cuts through direct physical contact, while laser cutting users a laser to cut through the material, the process requires directing the output of a high-powered laser. Put it simply, CNC cutting involves friction, and laser cutting is achieved by heat.

In addition, CNC cutting is more affordable when compared to laser cutting, the cost of a laser cutter contributes much to the reason. The precision that can be achieved with laser cutting is also incredible, you can get a level of precision and intricacy that is almost impossible through friction-based CNC cutting. When it comes to surface quality, laser cutters also provide excellent cleaner edges. And the biggest benefit of CNC cutting is that it can produce diagonal, curved, straight-lined, and more complex shapes easily with CNC programming. It also eliminates the possibility of human error.